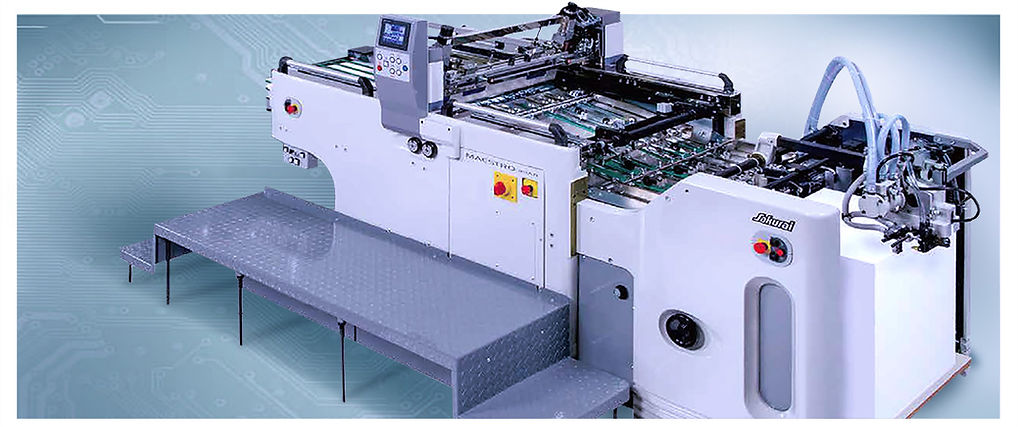

MS 102AX SERIES

SPECIFICATIONS

OPTIONAL EQUIPMENT

-

Double sheet detector (Mechanical/Ultra-sonic)

-

Piston sucker (Front pick-up feeder)

-

Push side lay (80AⅡ)

-

Variety anti-static devices

-

Sheet feed ball rack

-

Movable rebound stopper

-

Sheet cleaning roller unit (one side/both side)

-

Smaller cyl. Vacuum holes (102AX)

-

Screen part tensioners

-

Cross over stand

-

Air compressor (0.4kW)

-

High pile (+300mm)

-

Palettable feeder

-

Smart cover

-

Embossed stainless steel plate feeder board

-

Press down feed rollers and brushes

-

Pull side lay (80AⅡ)

-

Push/pull convertible side lays(R+L) (102AX)

-

Delivery board belt motor drive

-

Delivery board lowering system

-

Built-in front lay sensor

-

Suction feed belts

-

Dripless squeegee

-

Screen frame pull-out device

-

Screen frame air clamp device

-

Ink drip pan (at frame pull-out)

-

Motorized squeegee pressure control

-

Inverter speed control device (Digital indication)

-

Preset counter

-

Fixed rebound stopper (feeder side)

-

Fixed rebound stopper (delivery side)